Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

You’re about to commence a journey to create your own Simple AC-DC Power Converter. This DIY project will guide you through the process of transforming household AC into usable DC power for your electronics. With the right tools and a bit of patience, you’ll master the basics of circuit design, safety measures, and troubleshooting. Curious about where this newfound knowledge could take you? Let’s get started.

Understanding the Basics of AC and DC

Before diving into your AC-DC power converter project, it’s essential to grasp the fundamentals of AC (Alternating Current) and DC (Direct Current). AC is the type of electrical current that changes direction periodically, typically used in households and industries. It’s what powers your home appliances and lighting systems. On the other hand, DC flows in a single direction with a constant voltage, commonly found in batteries and electronic devices.

Understanding their differences is vital. AC is ideal for long-distance transmission due to less energy loss, while DC is suited for powering electronic circuits requiring a steady voltage. Your project will involve converting AC’s oscillating nature into a steady DC output, enabling you to power various electronic devices effectively.

Gathering the Necessary Tools and Materials

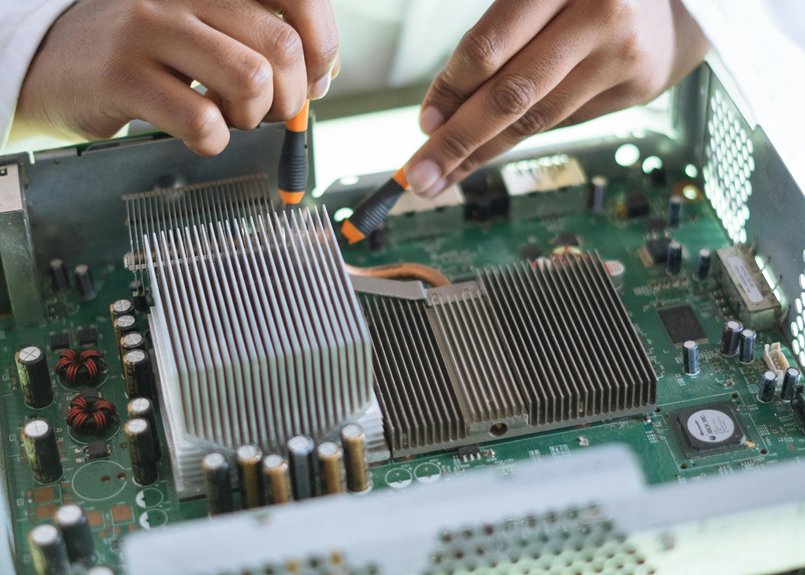

Now that you understand the basics of AC and DC, it’s time to gather the tools and materials for your AC-DC power converter project. Start by obtaining a soldering iron and solder; they’re essential for connecting components securely. You’ll also need a multimeter to test your connections and guarantee voltage levels are correct. Get a suitable transformer, bridge rectifier, and voltage regulator, as these are the core components of your converter. Don’t forget a breadboard and jumper wires for prototyping your circuit. A small screwdriver set will be handy for assembling and disassembling parts. Finally, grab some heat shrink tubing to insulate exposed wires. With these tools and materials, you’re well on your way to building your power converter.

Safety Precautions and Best Practices

While excitement may be building to plunge into the AC-DC power converter project, prioritizing safety is vital. First, make sure you’ve unplugged all power sources before beginning any work. Use insulated tools and wear rubber-soled shoes to minimize shock risk. Always double-check connections to avoid short circuits. Work in a dry, well-lit area to prevent accidents and enhance visibility.

Never handle components with wet hands, and keep flammable materials away from your workspace. It’s important to know basic first aid in case of electric shock. Familiarize yourself with the proper operation of a fire extinguisher, just in case. Finally, never rush the process. Take your time to understand each step, and don’t hesitate to consult additional resources if needed. Safety first!

Selecting the Right Transformer

Understanding safety measures lays the groundwork for a successful AC-DC power converter project. Now, let’s focus on selecting the right transformer. First, determine the input and output voltage requirements. If you’re converting 120V AC to 12V DC, you’ll need a transformer with a 10:1 turns ratio. Consider the current ratings too; make certain the transformer can handle the current your project demands. If you need 2 amperes, pick a transformer rated slightly higher, like 3 amperes, for safety. Also, check for efficiency and heat dissipation features. Look for a transformer with low idle current loss and proper insulation. Finally, make certain the transformer fits your project’s physical dimensions. With these considerations, you’ll guarantee your converter’s efficiency and reliability.

Assembling the Rectifier Circuit

Once you’ve selected the right transformer, it’s time to assemble the rectifier circuit, which is essential for converting AC to DC. Start by gathering four diodes to create a full-wave bridge rectifier. Arrange them in a diamond shape on your breadboard. Connect the AC terminals of the transformer to the two opposite points on the diamond, ensuring the correct polarity. The other two points will serve as the DC output. Make sure the diodes’ cathodes are oriented towards the positive output and the anodes towards the negative. This configuration efficiently rectifies the AC signal into a pulsating DC output. Double-check all connections for accuracy, ensuring there’s no risk of short circuits, which could damage your components.

Implementing the Smoothing Capacitor

With your rectifier circuit in place, you’ll now focus on smoothing the pulsating DC output using a smoothing capacitor. This component is essential for reducing voltage ripple, guaranteeing a more stable DC voltage. Start by selecting a capacitor with a voltage rating higher than your expected DC output. Typically, an electrolytic capacitor works well due to its high capacitance values. Connect the capacitor in parallel with the load. Confirm the capacitor’s polarity matches the circuit, with the positive lead connected to the positive DC output and the negative lead to the ground. This setup stores energy when the voltage rises and releases it when the voltage falls, effectively smoothing the output. Double-check connections to prevent possible damage or malfunction.

Testing and Troubleshooting Your Converter

Now that you’ve assembled your AC-DC power converter, it’s essential to verify the voltage output to guarantee it’s functioning correctly. Check each component connection to confirm everything is secure and in the right place. Don’t forget to manage heat effectively, as excessive heat can harm your converter’s performance and longevity.

Voltage Output Verification

Before you wrap up your AC-DC power converter project, verify its voltage output is reliable and matches your design specifications. Start by using a multimeter to measure the output voltage. Connect the multimeter’s probes to the converter’s output terminals. Make sure your multimeter is set to measure DC voltage. Note the reading and compare it to the expected output voltage. If it matches, great! If not, don’t panic. Check for any signs of faulty components or incorrect connections that might be affecting the output. Also, verify that your load is not drawing too much current, as this might cause voltage drops. Re-evaluate your circuit design if necessary. Remember, consistent results mean your converter is functioning correctly.

Component Connection Inspection

Once you’ve verified the voltage output, confirm all components are properly connected to avoid any functional issues. Begin by visually inspecting each connection. Make sure no wires are loose, frayed, or touching unintended parts. Double-check that polarized components, like diodes and capacitors, are oriented correctly. Misconnections can lead to failures or damage.

Next, use a multimeter to test continuity in your circuit. This verifies all parts are connected as intended, without unexpected breaks. If any connections seem faulty, re-solder them carefully. Additionally, inspect for any cold solder joints, which appear dull or cracked. These can disrupt performance.

If problems persist, consult the schematic and trace each connection. Systematically troubleshoot by isolating sections to pinpoint issues. Your diligence now prevents headaches later.

Heat Management Techniques

While guaranteeing your AC-DC power converter functions at its best, managing heat is essential to prevent damage and maintain efficiency. Start by installing heat sinks on components like diodes and transistors. These dissipate heat effectively, keeping temperatures in check. Consider adding a small fan to enhance airflow, especially if you’re dealing with higher power levels. Position the fan to direct air across the most heat-sensitive parts.

Regularly check the converter for hot spots by feeling the components after it’s been running for a while. If you notice any overheating, double-check your connections and verify nothing is obstructing airflow. By maintaining a clean and well-ventilated setup, you’ll prolong your converter’s lifespan and optimize performance. Remember, effective heat management is key to a reliable power conversion.

Exploring Applications and Next Steps

As you complete your AC-DC power converter project, consider the wide range of practical applications this device offers. You can use it to power small electronics, charge batteries, or even integrate it into renewable energy systems like solar panels. It’s a versatile tool that can bring your DIY projects to life, whether you’re building a custom lighting system or experimenting with robotics.

Now, think about next steps. Test your converter with different loads to understand its capabilities and limitations. Document your findings—this helps in troubleshooting and future improvements. If you’re looking to expand your skills, explore more advanced topics like voltage regulation or efficiency optimization. Keep experimenting, learning, and tinkering, and you’ll find new ways to apply your skills in real-world scenarios.

Conclusion

You’ve now got the fundamentals of converting AC to DC under your belt! With your trusty soldering iron and multimeter, you’ve built a bridge rectifier and learned to guarantee a stable output using a voltage regulator. Remember, safety first, but don’t be afraid to push the envelope and explore new applications. Whether it’s powering small gadgets or diving into more complex projects, you’ve got a solid foundation to electrify your skills and light up your future endeavors!